Modern and flexible machinery for mold and tool making

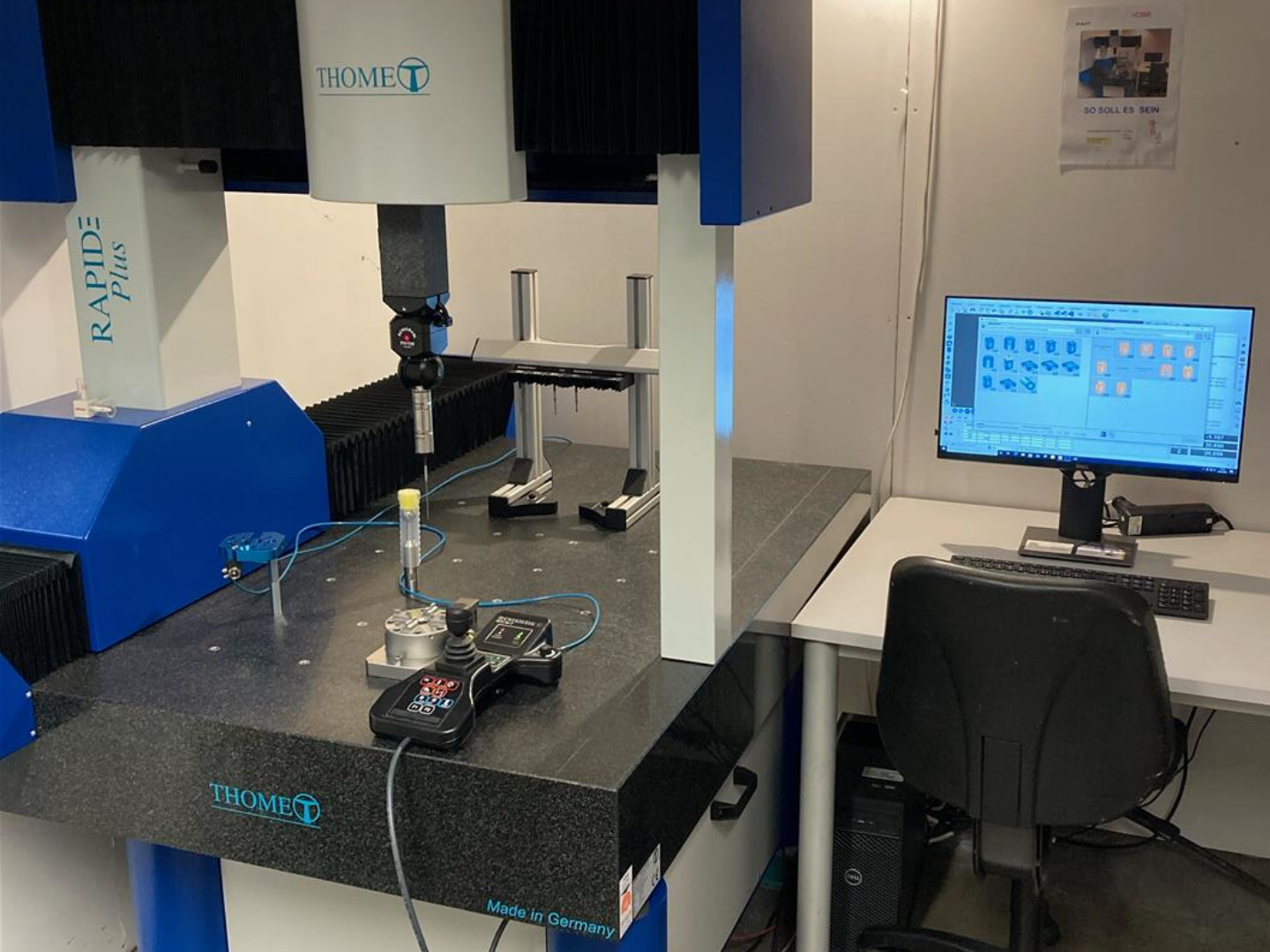

For quality control, all relevant components are inspected during the production process using state-of-the-art measuring technology, in some cases directly on the production machines.

In addition, a coordinate measuring machine Thome Rapid Plus CNC is used, measuring tactilely and by scanning. A hardness tester is also available.

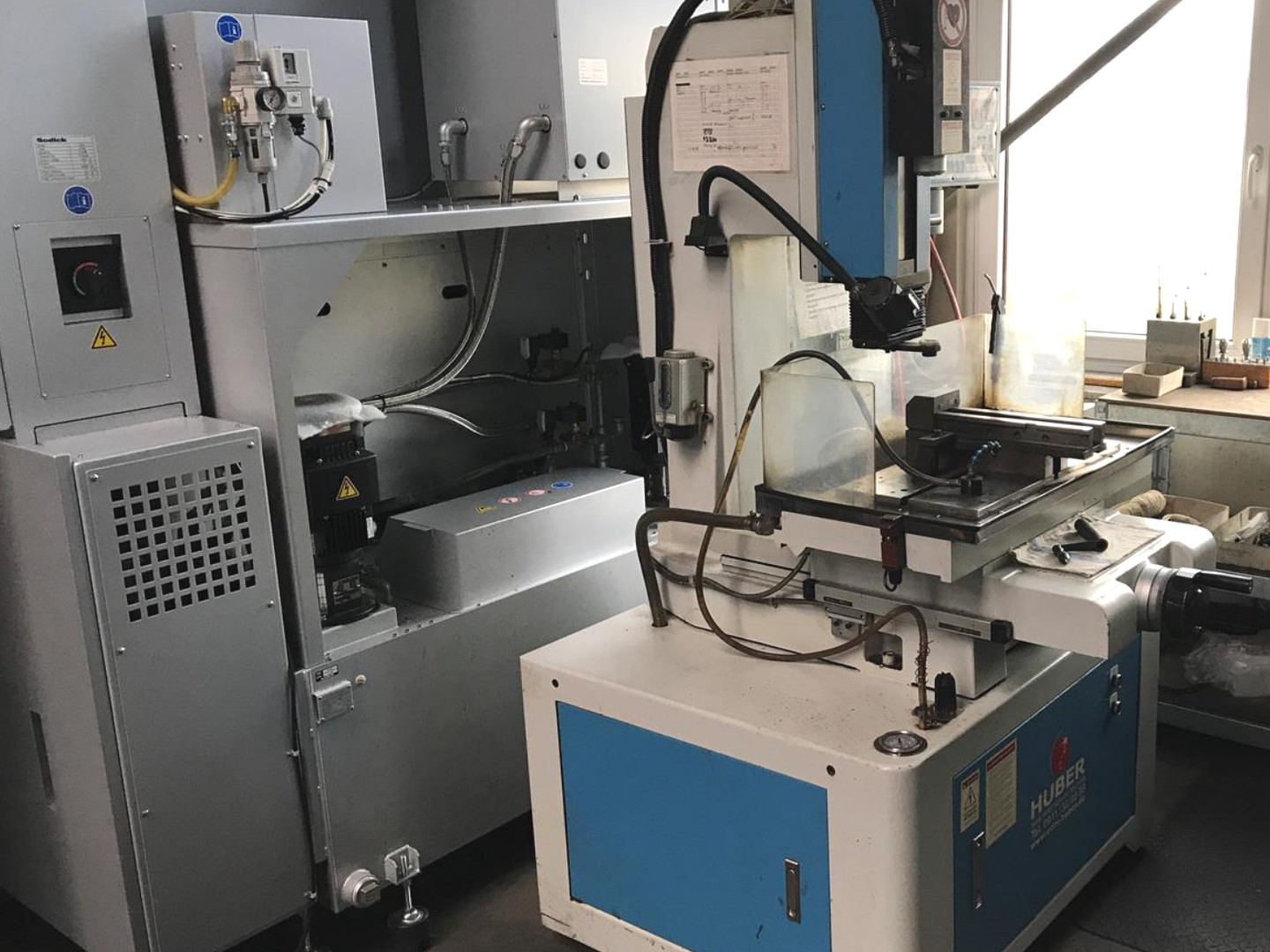

Eroding

- 2x SODICK die-sinking machines

- 1x INGERSOLL die-sinking machine

- 2x MITSUBISHI wire eroding machines

- 1x start hole eroding machine

Milling

- 1x POS 5-axis machining center

- 2x POS 3-axis machining center

- 1x DMC 3-axis machining center

- 1x RÖDERS 3-axis HSC machining center

- various conventional milling machines

Turning

- 1x CNC lathe

- 2x conventional lathes

Drilling

- 2x Donau column drill

Grinding

- 4x flat grinding

Spotting press

- 1x Gustav Hessmert

Laser welding

- 1x OR-LASER 120w